Bryce C

DFW

I replaced my pressure pump yesterday. My goodness that thing was ancient and had so much rust and shmegma on the bottom side from small unaddressed leaks it was ridiculous. I was able to salvage the mounting plate with a little dremeling.

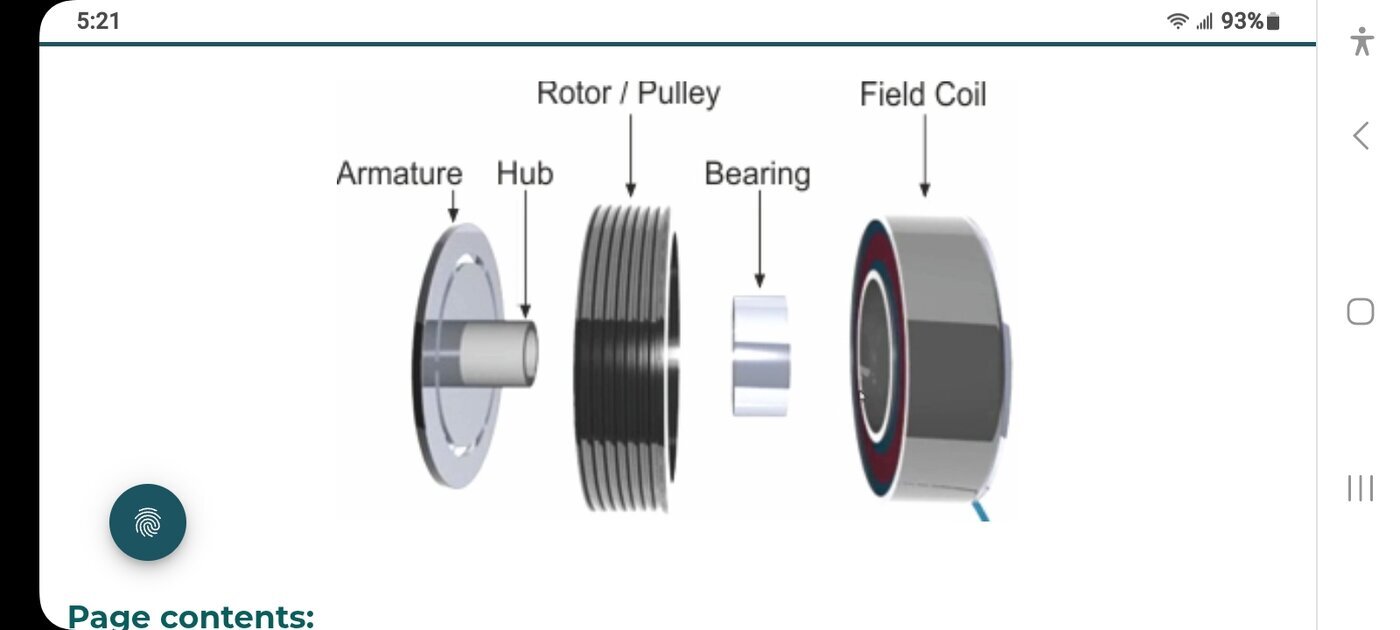

Now my pump clutch is seized, or stuck in the engaged mode so the pressure pump just stays on whenever the tm is running. It worked fine before. It took a lot of force with my gear puller to remove the pulley from the old pump. I released the 2 allen set screws first, but damn that thing was on there. After installing it I blasted the face of it with wd 40 and let it sit overnight, still stuck this morning. Anything that can be done to set it free? Could it be a shot bearing, or? A new one is $350. Should I just get a new pump clutch?

Now my pump clutch is seized, or stuck in the engaged mode so the pressure pump just stays on whenever the tm is running. It worked fine before. It took a lot of force with my gear puller to remove the pulley from the old pump. I released the 2 allen set screws first, but damn that thing was on there. After installing it I blasted the face of it with wd 40 and let it sit overnight, still stuck this morning. Anything that can be done to set it free? Could it be a shot bearing, or? A new one is $350. Should I just get a new pump clutch?